A Sovol SV06. It's a very well reviewed printer that has a lot of community support, although the paid support is supposed to be poor. It's also a recommended printer for 3D printer newbies, like me.

It took me about an afternoon to assemble the printer, calibrate it, and print Benchy. It came out great. No problems at all after I got the firmware update from Sovol's website. A couple successful prints later and some higher-grade PLA filament (that's the stuff the printer uses to print), I went on to print an alto sax mouthpiece. The one I settled on was this one. The instructions and build files are here.

The print came out a bit better than advertised and all I had to do is gently sand the tip of the mouthpiece to round off the pointed corners. I didn't bother with any of the other sanding instructions. I borrowed my wife's alto and gave it a toot: I could play the entire keyed range. Mind you, this is a horn that needs a full overhaul and I haven't played any horn for any length of time for at least 5 years. Also, while the reed was in original, sealed, packaging, it was probably 3 years old. So, I'll call this a successful test.

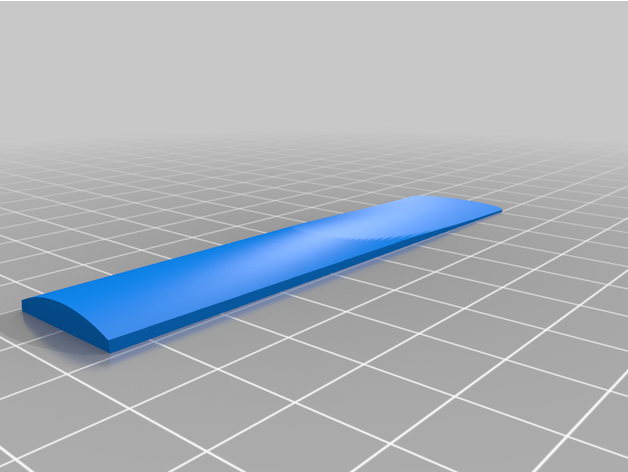

I then pushed my luck and 3D printed a reed. The reed came out about twice as thick as a standard Vandoren 2.5. I was barely able to put it on the mouthpiece with the stock Selmer ligature I was using. I tried blowing through it and there was no vibration at all. So, research must continue.

Note that I used PLA filament in all my tests. The reed is supposed to be printed with PETG and the mouthpiece is supposed to be printed with PLA+.

I see that there are a bunch of other mouthpieces, reeds, end caps, mouthpiece caps, and ligatures you can print.

It took me about an afternoon to assemble the printer, calibrate it, and print Benchy. It came out great. No problems at all after I got the firmware update from Sovol's website. A couple successful prints later and some higher-grade PLA filament (that's the stuff the printer uses to print), I went on to print an alto sax mouthpiece. The one I settled on was this one. The instructions and build files are here.

The print came out a bit better than advertised and all I had to do is gently sand the tip of the mouthpiece to round off the pointed corners. I didn't bother with any of the other sanding instructions. I borrowed my wife's alto and gave it a toot: I could play the entire keyed range. Mind you, this is a horn that needs a full overhaul and I haven't played any horn for any length of time for at least 5 years. Also, while the reed was in original, sealed, packaging, it was probably 3 years old. So, I'll call this a successful test.

I then pushed my luck and 3D printed a reed. The reed came out about twice as thick as a standard Vandoren 2.5. I was barely able to put it on the mouthpiece with the stock Selmer ligature I was using. I tried blowing through it and there was no vibration at all. So, research must continue.

Note that I used PLA filament in all my tests. The reed is supposed to be printed with PETG and the mouthpiece is supposed to be printed with PLA+.

I see that there are a bunch of other mouthpieces, reeds, end caps, mouthpiece caps, and ligatures you can print.