I would not recommend this modification unless the MPC adjustments don't get you there and/or the instrument was really cheap

George

It wasn't particularly cheap, but as it is now, it is just what we call a "hanger" .. just hang it above the mantle and knowingly answer your guests who ask, "what is that?"

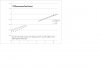

I did some measurements on the TSO (tárogató shaped object). The telescoping gauges available could not reach the entire

lengths of the two instrument joints, but the trends seemed obvious. The first figure shows the inner diameters vs

distance from the tip of the tenon on the upper joint. The bore is very close to circular at all distances except where

it is narrowest, so I do not believe the distortions from conical are due to shrinkage of the wood. I do restorations of

antique guitars and need to know how wood shrinkage works.

The spreadsheet program allowed fitting a line to the data for the lower joint, and showed a taper of 1:18.45. In the

figures, this line is the upper one at small distances. The other line has a slope of 1:17.5 as previously suggested by

George from similar measurements on his instrument.

The second figure is a detail of the data, showing what is happening in the upper joint. Clearly there is a constriction

from the top end to about 1" in, and the bore remains narrower than either the 1:17.5 or the 1:18.45 line up to about

7-8". After that, it flares out slightly and the effect can be seen by eye when looking inside the bore. I overestimated

the step in the bore between the upper and lower joints in my previous post - the step is due to the flaring.

If the bore needs be conical (except, perhaps, the last 1-2 inches at the top and some part of the bell) the oversized

portion of the upper joint from 8-10" should be filled with something and worked back down to make a smooth transition

between the two joints. Again following George, and definitely at my own risk, I would make a conical tool with 1:18.45

taper and enlarge the upper extreme of the bore; any filler material placed in the flared area could be leveled with the

same tool.

I too made a cone of maple at 1:18.5 taper. A hacksaw blade was tapered at one end, sharpened, and glued into a slot

running the length of the cone to make a single flute reamer. It would work like a violin-peghole reamer.

Incidentally, the URL

http://mysite.verizon.net/res8o1o8/SopCompare.htm shows measurements on two C soprano saxes, with

tapers of about 1:16.5 ("Taper" = 0.060 means 1:16.5). Chen, Smith, and Wolfe

(

http://www.phys.unsw.edu.au/jw/reprints/ChenetalAA.pdf) indicate that the half angle of the taper of a soprano sax is

1.74 degrees, or 1/(tan(1.74deg x2)) = 1:16.4 . The TSO measurements of 1:17.5 to 1:18.5 are not much different.

Now that George has commented (again, I think) that the bore should have a cylindrical section, I will refrain from

working on the bore for a while. Clay in the mouthpiece has not done enough.

Is anyone willing to make similar measurements on an instrument that plays decently in tune? What I want to know is: How

long is any cylindrical portion of the bore nearest to the mouthpiece.

....... C.S.