In another thread that I cannot find, we were talking about which screwdrivers and other tools that we liked.

In one particular subject we chatted about Ferrees screwdrivers and how brittle the tips were.

Recently Ferrees offered just the tip part for sale now. Interesting that it had replacement blades but replacements were not available for a long time. BUT now they are !!

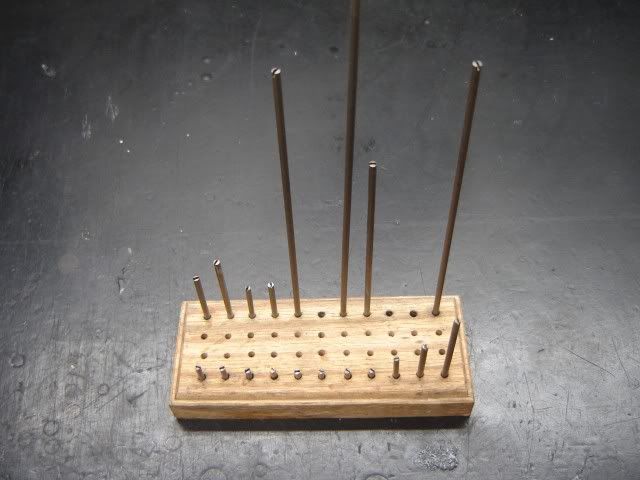

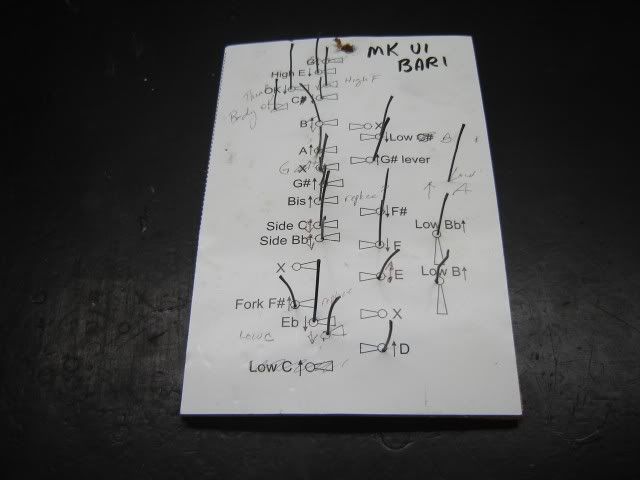

Anyways, here are a few pictures that show a broken tip, the tip profile, the back end of the blade which has flat spots, which the two opposing screws screw down on.

BELOW: The two opposing set screws (screwed out) which tighten down on the flat part of the blade

BELOW: The top tip is the profile of the blade. This is a new blade.

middle: is the broken tip

lower: the edge of the back of the blade is flat which allows the set screws to prevent the rod from rotating.

In one particular subject we chatted about Ferrees screwdrivers and how brittle the tips were.

Recently Ferrees offered just the tip part for sale now. Interesting that it had replacement blades but replacements were not available for a long time. BUT now they are !!

Anyways, here are a few pictures that show a broken tip, the tip profile, the back end of the blade which has flat spots, which the two opposing screws screw down on.

BELOW: The two opposing set screws (screwed out) which tighten down on the flat part of the blade

BELOW: The top tip is the profile of the blade. This is a new blade.

middle: is the broken tip

lower: the edge of the back of the blade is flat which allows the set screws to prevent the rod from rotating.

Last edited: