Sometimes the simple method is the best.

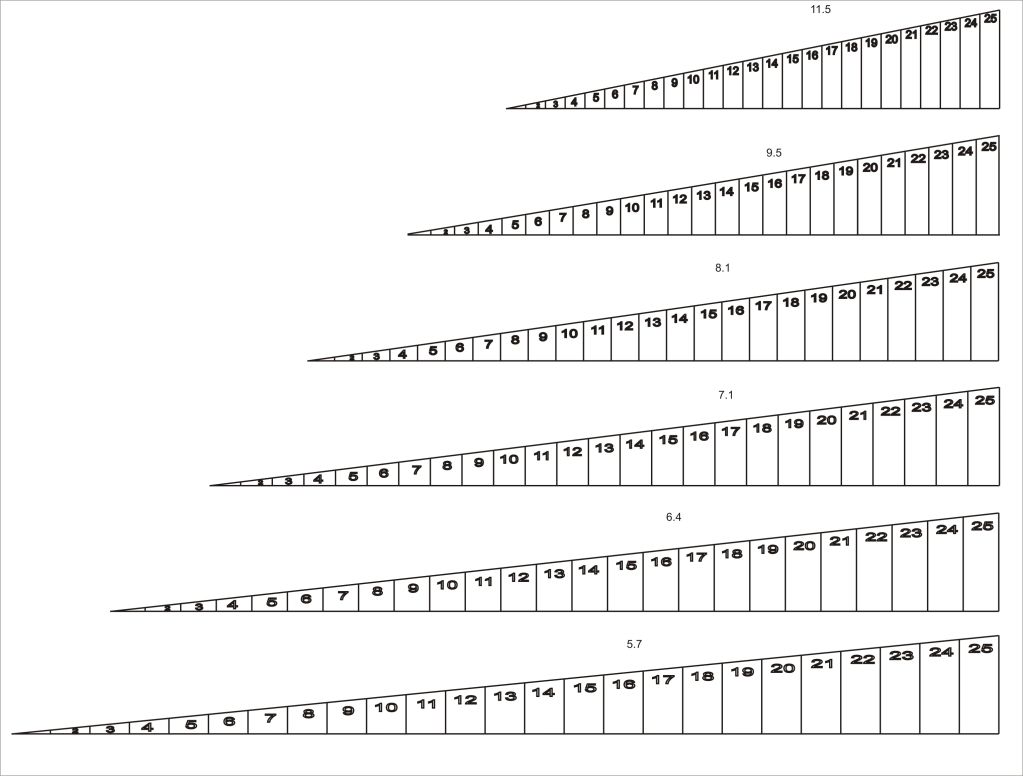

If you were to measure tone hole openings "venting capability" value for dollar the pieces displayed above by two members would more than suffice, if you were to approach this in an engineering perspective where you needed an exact measurement which could be repeatable and digitally displayed, then this could also be achieved but would involve quite a labour intensive build to create, but do-able.

If you were to measure tone hole openings "venting capability" value for dollar the pieces displayed above by two members would more than suffice, if you were to approach this in an engineering perspective where you needed an exact measurement which could be repeatable and digitally displayed, then this could also be achieved but would involve quite a labour intensive build to create, but do-able.

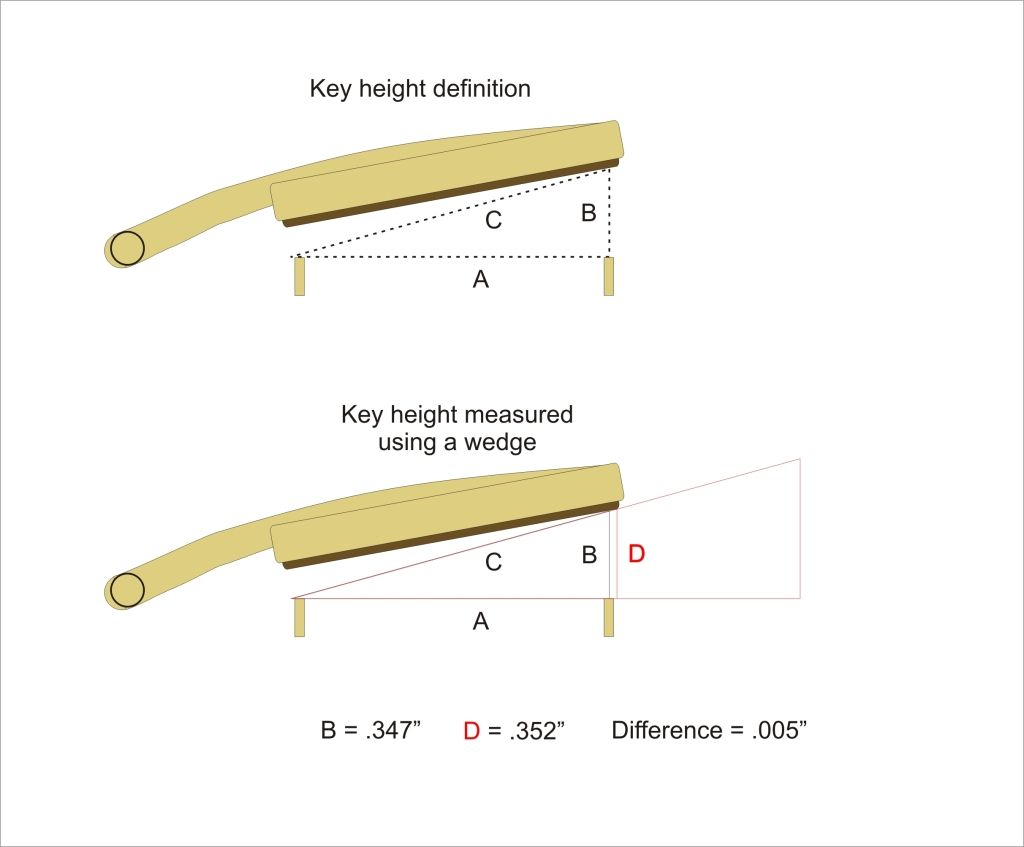

at one height for better intonation, you'd have to adjust that height for

at one height for better intonation, you'd have to adjust that height for  -- or, of course, set it at a happy medium between the two. I'd also think that you'd have to take the key heights of the surrounding tone holes into account, too, which would make it all a rather complicated affair.

-- or, of course, set it at a happy medium between the two. I'd also think that you'd have to take the key heights of the surrounding tone holes into account, too, which would make it all a rather complicated affair.